OSRAM Digital Systems is now part of Inventronics.

The same people will support you with the same quality products, the same services and more – as in the last 111 years.Our Experts support you

Read the latest News and Updates from our Product Experts.

If you have further questions to our products, systems and solutions, do not hesitate to get in direct contact with our Experts.

Industrial

In hardly any other area of application are the advantages of modern LED lighting as obvious as in the industrial sector – with up to 85 % savings potential in electricity costs, significantly extended maintenance intervals, longer service life and unprecedented light quality. With high-quality LED drivers, LED modules and light management systems from Inventronics, you can offer your industrial customers convincing alternatives from a single source – for the cost-saving, eco-friendly, sustainable and digitally controllable lighting of the future!

From conventional to intelligent: HubSense

With HubSense, we offer the possibility of transforming existing lighting systems into a flexible, wirelessly communicating lighting infrastructure during modernization. How does this work? Without great effort! Because HubSense is simple and intuitive. This easily scalable retrofit solution makes the planning, configuration and commissioning of wireless lighting control easier than ever before – from convenient planning with the web app to commissioning via smartphone and mobile app to simple operation of the system – for individual offices, corridors, conference rooms or open-plan offices.

With the HubSense system you work more cost-effectively in every project phase – from planning and installation to handover and use.

Area and Sports

Wherever a lot of light is needed, area and sports lighting systems provide exceptional brightness, excellent visibility and a high level of safety. As a global market leader in the lighting industry, Inventronics offers you everything you need for the planning and design of state-of-the-art, energy-saving and digitally controllable LED systems for area or sports lighting.

Find easily your desired products with our Online Tools

Lighting Designer

The Lighting Designer online tool helps to identify the right combination of LED modules and driver based on your technical specifications of your luminaire project.

Driver Selector & Digital OT-Poster

With our Driver Selector & Digital OT-Poster you can simply find your desired LED driver and create your individual driver overview by selecting the product families, characteristics, features, applications or filter by attributes for your needs – always with the latest product portfolio.

Digital Flex/Area-Poster

With the digital Flex/Area-Poster you can simply create your individual OSRAM LINEARlight Flex or Back/BoxLED overview by selecting the product families, classes and attributes you are interested in – always with the latest product portfolio (daily updated).

Latest News

Search only Expert posts

Search in all content

-

Good talks, great success

Inventronics at the “Light + Building 2024” in Frankfurt As a global technology leader, Inventronics enjoys an excellent standing as a highly trustworthy partner to the lighting industry. This was confirmed once again at this year’s “Light + Building” in Frankfurt am Main, Germany. Our … [more]

-

Brand-new: OPTOTRONIC FIT 100/150 D NFC HV L

All-new LED drivers with high output voltage for industry, warehouses, offices and retail Our brand-new OPTOTRONIC FIT 100/150 D NFC HV L LED drivers with high output voltage are now on stock. With a DALI version to follow soon, these new devices are available as … [more]

Categories: LED Driver -

Homogeneous area lighting with integrated wireless control

PrevaLED Flat AC BL/CA 230 V G3 light engines with Casambi or Bluetooth technology Beautiful, homogeneous lighting is needed in many places, for example in hotels and restaurants, in offices and public buildings or in the retail business. In many of these application cases, large … [more]

Categories: LED Modules -

The first DALI+ certified, wireless LED driver comes from Inventronics

Inventronics presents the first DALI+ with Thread certified, wireless LED driver at Light + Building 2024, the international industry meeting place for lighting and building technology. Harnessing the advantages of the DALI-2 standard for lighting, DALI+ extends its features and benefits to the wireless realm. … [more]

Categories: LED Driver -

Experience outstandingly flexible and sophisticated lighting design

Transforming lighting solutions: OT Wi 24V CA LED driver enhanced with CASAMBI control In response to the evolving needs of the lighting industry, the OPTOTRONIC Wireless Indoor LED driver family from Inventronics offers a well-thought-out upgrade that now includes a larger CASAMBI product selection. From … [more]

Categories: LED Driver -

Unveiling the future of connected lighting with the QBM IoT GATEWAY

Illuminate intelligently, save energy, and control intuitively! HVAC systems lighting installations consume huge amounts of energy. For this reason, sensor integration and thoughtful lighting settings are essential for reducing energy consumption. Lighting control becomes paramount because clever adjustments enable increased energy savings while at the … [more]

Categories: Light Management SystemsApplications: Office -

Available now: BoxLED XS Core Product 12V G5 expands the product family

Slim LED chains for highly effective sidelighting in flat light boxes The fifth generation of the BoxLED Core family announced last year has now been joined by another variant, the new BoxLED XS CP 12V G5! With these particularly slim LED chains, we are adding … [more]

Categories: LED Modules -

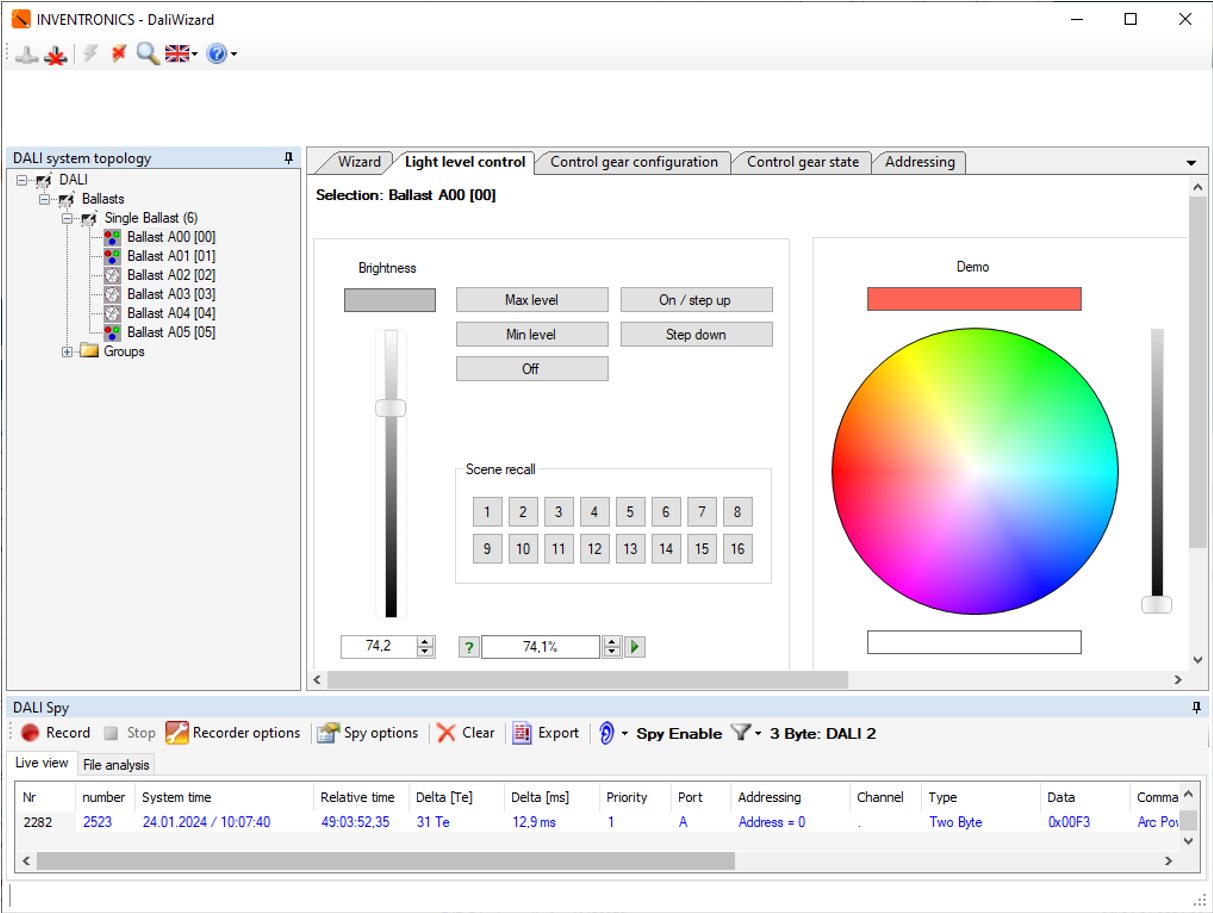

DALI Wizard 3.0 available for download

The practice-oriented DALI commissioning and testing tool – now also for multi-channel DALI drivers (TW, RGBW) DALI Wizard is a software tool for the fast and efficient commissioning of LED drivers in a DALI network. It also allows sending DALI commands, e.g. for switching and … [more]

Categories: LED Driver -

Successful trade fair discussions in Dubai

Inventronics at the der “Light + Intelligent Building Middle East 2024” From 16.01. to 18.01.2024, Inventronics took part in the “Light + Intelligent Building Middle East 2024” in the World Trade Center of Dubai. We presented our products branded with both Inventronics and OSRAM at … [more]

-

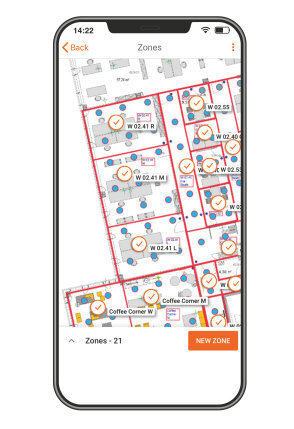

HubSense R2G App for intuitive lighting control

HubSense R2G simplifies smart lighting installation, offering seamless control and configuration via smartphone HubSense R2G (Ready to Go) App by Inventronics: Intuitively configure and control light via smartphone. Ideal for smart fitting installers, R2G simplifies installations. It’s a basic commissioning app for Bluetooth mesh devices, … [more]

Categories: Light Management Systems